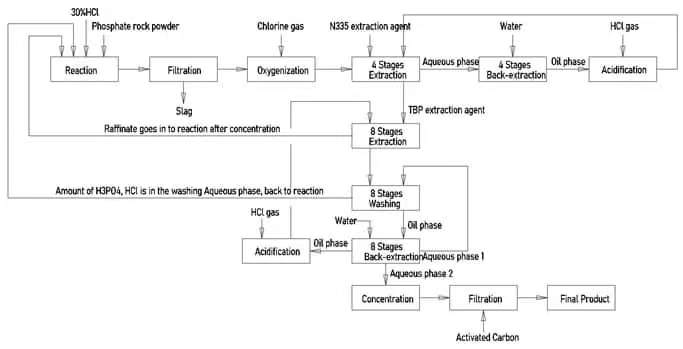

PROCESS DESCRIPTION

Using hydrochloric acid method instead of the traditional sulfuric acid method to produce food-grade phosphoric acid can make effective use of low-grade phosphate rock and simultaneously solve the treatment problem of hydrochloric acid, which is massively produced from the upstream production market.

Add phosphate rock and hydrochloric acid to the reaction tank, stir to dissolve, react and heat to a certain temperature, then keep it for a certain period of time. After that, cool, settle, filter and oxidize the reaction liquid to obtain the crude phosphoric acid liquid containing impurities of Ca2+, Fe2+, Al3+, and Si4+. The crude phosphoric acid liquid is treated with extraction of iron, purification to become pure phosphoric acid liquid, and finally through the concentration to obtain high-quality phosphoric acid and by-products CaCl2 and ferric chloride.